A frequent question asked is if two rows of sealant should be used in a precast joint. The common solution is to just use one row of sealant because it is the most economical. Those who use two will cite that they see the extra sealant as insurance of a good seal. There are logical reasons to use only one row or to choose two rows (or more) of sealant in a joint.

First, flexible sealants such as CS-102 are laterally displaced in the joint during compression. The amount they flow is dependent on the weight of the structure above, or the amount of force applied to compress the sealant. Most forces apply 300 lbf/ft or more during compression. A 30-ton casting and a 15-ton casting can have the same force per linear foot of joint if the perimeter of the 30-ton casting is twice that of the 15-ton casting. This is an important concept to remember, and we have a separate blog that describes this in more detail.

The purpose of a sealant or gasket is to prevent water penetration at the seam of the casting units. There are two seams on every joint, an inside seam, and an outside seam. In a septic tank, for instance, the inside seam of a two-piece unit is the interface of the wastewater and the casting assembly. The outside seam is the interface of groundwater and the casting. The goal of the sealant is to prevent both infiltration and exfiltration. This is an important concept to consider when determining to use one row or two.

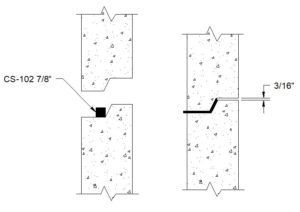

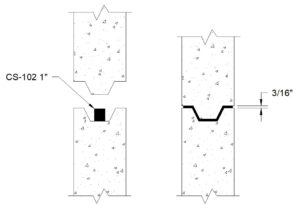

In a mid-seam wastewater holding tank, the joint is usually either a ship lap or a tongue and groove. When using one row of sealant in a shiplap configuration, the producer will choose to lay it on the upper or lower shoulder of the bottom casting (figure 1).

Depending on the configuration, this will typically provide some “squeeze out” toward the inside or the outside of the casting. In a tongue and groove joint the sealant is usually laid in the groove which is in the center of the joint (figure 2).

It is possible that enough force can be applied to allow for the flow of sealant to provide internal and external squeeze out.

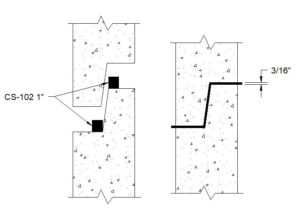

The concept above is important when considering whether to use one row or two. Another question we might ask a producer is which is more critical: preventing infiltration or preventing exfiltration? If the answer is both, and if the sealant cannot be placed in the center of the casting, we will likely suggest using two rows of sealant (figure 3).

On the other hand, if the main concern is exfiltration, then using one row might be sufficient, and the location of the sealant should be such that the sealant extrudes toward the inside, allowing a sealant interface with the inside seam of the casting.

Do you have questions about which sealant or which amount would best serve your project?